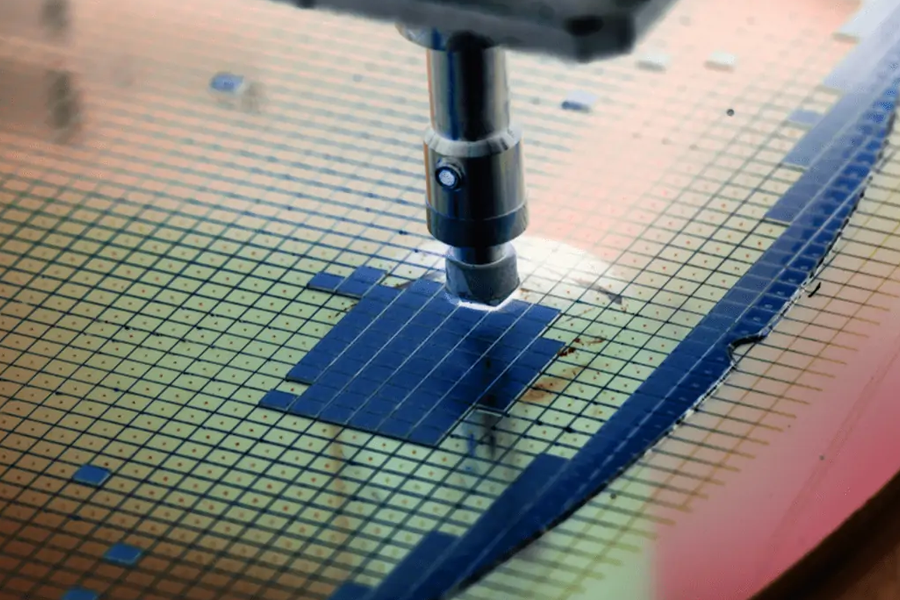

Image Source: andcable.com

Extreme Ultraviolet (EUV) lithography has emerged as the cornerstone of advanced semiconductor manufacturing, but the sustainability of this technology depends on next-generation light sources. Laser-Produced Plasma (LPP) has carried EUV into production, yet its limitations in scalability, stability, and cost are increasingly visible. Free-Electron Lasers (FELs) are being studied as the next leap, offering higher stability and power through accelerator-based systems. Their potential lies not only in output but in the architecture that makes them viable for high-volume manufacturing. Erik Hosler, a specialist in advanced manufacturing strategies, understands that FELs could become integral to semiconductor roadmaps if their design challenges can be addressed. His work underscores the importance of examining how FEL system architecture supports both performance and integration.

Understanding FEL architecture is crucial to evaluating whether these systems can transition from research facilities to semiconductor fabs. Each major component, like the injector, the undulator, energy recovery systems, and modular designs, plays a critical role in determining performance. These technologies must work together seamlessly to deliver reliable EUV light at scale. Examining how they function and what innovations are emerging provides a window into both the promise and the complexity of FEL deployment.

The Role of the Injector

The injector serves as the starting point of the FEL system, producing a beam of electrons that will ultimately generate EUV light. Its quality determines the stability, coherence, and overall performance of the downstream system. Electron sources must deliver beams with extremely low emittance and high consistency, since even minor variations can ripple through the system and reduce light quality.

One of the key innovations in injector design is the use of Superconducting Radiofrequency (SRF) technology. SRF injectors allow continuous-wave operation, an essential requirement for semiconductor fabs that demand uninterrupted output. Their efficiency also reduces power losses, helping to manage one of the system’s biggest challenges, which is energy consumption. By advancing injector stability, engineers are laying the foundation for FEL systems that can meet the rigorous standards of high-volume manufacturing.

The Undulator: Heart of FEL Radiation

Once electrons are accelerated, they pass through an undulator, a structure composed of alternating magnetic fields. This interaction forces the electrons to oscillate, producing coherent radiation in the EUV spectrum. The undulator is, in many ways, the core of FEL innovation. Its design directly impacts the wavelength, power, and coherence of the light produced.

Precision is everything in undulator construction. Magnetic field uniformity must be maintained at nanometer tolerances to ensure beam quality. Researchers are exploring variable-gap undulators, which allow tuning of the radiation wavelength, adding flexibility for semiconductor processes. These innovations make FELs more adaptable than LPP systems, which are constrained by fixed source physics. The undulator’s development is therefore not only a technical challenge but also a driver of FEL’s comparative advantage.

Energy Recovery and Efficiency

Energy demands are among the greatest hurdles for FEL deployment in fabs. Operating accelerators at the scale required for EUV production consumes significant electricity, which raises both cost and sustainability concerns. Energy Recovery Systems (ERS) aim to address this issue by recapturing energy from spent electron beams and feeding it back into the accelerator cycle.

This approach dramatically improves efficiency. Instead of discarding electrons after a single pass, recovery systems recycle them, reducing both operating costs and thermal loads. For fabs, this is critical: energy efficiency translates directly into economic viability. Without robust ERS designs, FELs risk being prohibitively expensive to run. Ongoing innovations in superconducting linac design and beam recirculation are central to making FELs not just technically feasible but commercially realistic.

Industry Perspectives on Innovation

The development of FEL architecture is shaped not only by engineering challenges but also by industry expectations. Semiconductor manufacturers are less concerned with theoretical maximums and more focused on reliability, cost, and integration. As research progresses, the emphasis is on turning architectural innovations into practical advantages that align with fab operations.

Erik Hosler emphasizes, “It must impact society at large. The value of the computations it performs exceeds the cost to build and operate the computer.” While his statement refers broadly to technological adoption, it applies directly to FELs. Their value must outweigh the immense investment in building and running them. For semiconductor manufacturers, it means FELs must prove not only to be technically superior but also capable of enabling new levels of efficiency and output at scale. It underscores the need for FEL architecture that is not only powerful but also economically sustainable and socially impactful.

Collaborative Development Across Disciplines

Building FELs for semiconductor fabs is not solely a physics challenge. It requires collaboration across accelerator science, materials engineering, and semiconductor manufacturing. For example, aligning beamline design with lithography optics involves expertise from both fields. Similarly, developing superconducting components that can operate reliably at fab duty cycles requires cross-disciplinary innovation.

Collaboration also extends to industry consortia and public-private partnerships. FEL development is too resource-intensive for a single company or lab to pursue in isolation. By pooling resources, the semiconductor ecosystem can accelerate progress and spread costs, making adoption more achievable. The modular nature of FEL innovation makes it well-suited to such collaborative approaches, where contributions from multiple stakeholders can be integrated into a unified architecture.

Toward Scalable FEL Architectures

The future of FEL systems for EUV lithography lies in scaling these architectural innovations into deployable tools. Injectors must become more stable, undulators more precise, and energy recovery systems more efficient. Modular design will continue to develop, allowing fabs to adopt FELs in configurations that suit their unique constraints. Success will depend on engineering excellence and the ability to align technical achievements with the practical economics of semiconductor production.

The shift from LPP to FEL is not simply a change in light-source technology because it represents a rethinking of how lithography infrastructure is designed and deployed. By focusing on injectors, undulators, energy recovery, and modularity, the industry is laying the groundwork for a new generation of semiconductor fabs. Suppose these systems can deliver on their promise. In that case, FELs may define the next chapter of Moore’s Law, providing both the power and adaptability needed to sustain progress in an era of unprecedented complexity.