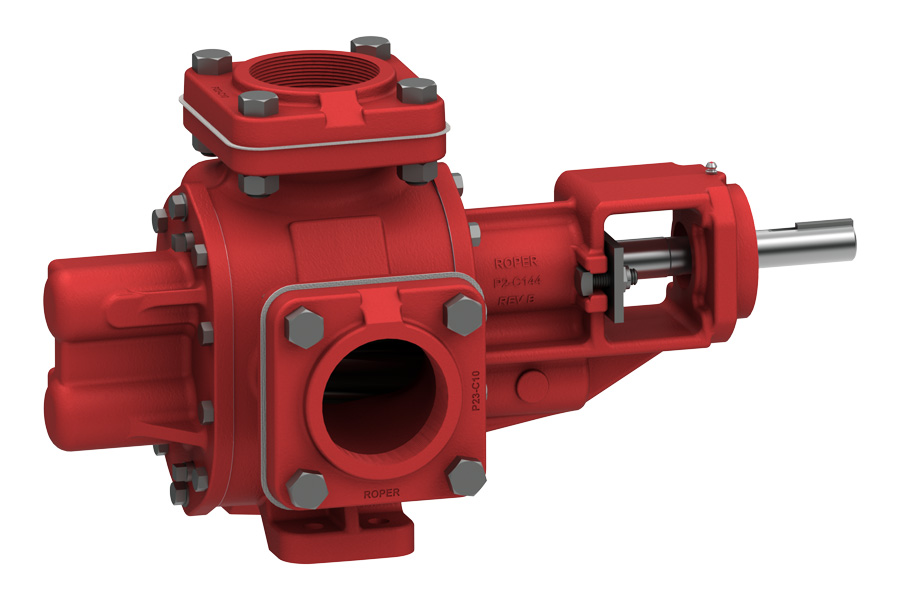

Image Source: roperpumps.com

In the industrial world, moving thick, viscous liquids efficiently and safely is no small feat, especially when the application demands consistent high pressure and elevated temperatures. From lubricating heavy machinery to transferring heat transfer fluids in extreme environments, having the right pump makes all the difference. This is where gear pumps, particularly lube oil pumps and high temp oil pumps, play a crucial role.

If you’re working with fluids like lubricants, polymers, resins, or high-temperature oils, choosing the correct gear pump is vital. In this guide, we’ll explore how gear pumps function, why they are ideal for viscous fluids, and what to consider when selecting one for demanding industrial applications.

Understanding Gear Pumps and Their Role in Viscous Liquid Transfer

Gear pumps are a type of positive displacement pump designed to move fluids through the action of rotating gears. They trap fluid between the teeth of the gears and the casing, then carry it from the inlet to the outlet in a steady, controlled stream.

What sets gear pumps apart is their ability to deliver:

- Pulse-free flow

- High precision

- Reliable performance with viscous fluids

- Excellent performance under high pressure

Because of these traits, gear pumps are often the preferred solution when dealing with oils, adhesives, heavy lubricants, and thermal transfer fluids.

Why Gear Pumps Are Ideal for Viscous Fluids

Viscous liquids, like lubricants and heavy oils, are resistant to flow and often require greater force to move. Many traditional pump types struggle with thick fluids, leading to uneven flow or mechanical wear. Gear pumps, however, are built to thrive in such environments.

Key Advantages Include:

Constant Flow Rates:

Gear pumps maintain a consistent flow, even as fluid thickness changes with temperature or pressure.

Self-Priming Capabilities:

They can start pumping without needing to be filled beforehand, ideal for applications where fluids may settle or cool.

Handles a Wide Range of Viscosities:

From low-viscosity fuels to high-viscosity grease, gear pumps can handle it all without compromising efficiency.

This makes them perfect for applications such as lube oil pumps, which need to provide precise lubrication in engines or manufacturing equipment under varying conditions.

Meeting High-Pressure Requirements

High-pressure environments are common in industries like chemical processing, manufacturing, and power generation. The right gear pump can deliver fluids under extreme pressure while maintaining durability and performance.

High-Pressure Gear Pump Features:

Tight Tolerances:

Reduce fluid leakage and increase volumetric efficiency.

Sturdy Construction:

Built with high-strength metals that can withstand pressure and stress.

Compact Design:

Gear pumps are smaller than many other high-pressure pumps, making them ideal for confined spaces.

Choosing a gear pump for a high-pressure environment requires balancing pressure capability with flow rate, fluid type, and operational safety.

Handling High Temperatures: What to Know

When working with heated fluids like thermal oils, molten resins, or high-temp lubricants, standard pumps may fail due to material limitations or seal degradation. That’s where high temp oil pumps come into play.

High Temp Oil Pump Capabilities:

Heat-Resistant Materials:

Made from alloys and seals that can handle temperatures above 400°F (204°C).

Minimal Thermal Expansion:

Ensures precise operation even as materials expand under heat.

Thermal Insulation:

Some are designed to reduce heat loss and protect nearby components.

Whether you’re transferring heat transfer fluids or circulating oil in high-temperature reactors, a high temp oil pump offers the durability and precision you need.

How to Choose the Right Gear Pump

Choosing the right gear pump involves a careful assessment of your specific application. Here are the most important factors to consider:

1. Viscosity of the Liquid

Heavier fluids require pumps with slower speeds and larger clearances to reduce internal wear. Knowing your fluid’s viscosity at operating temperature is critical.

2. Operating Pressure

Ensure the pump can operate consistently at your required discharge pressure. Higher-pressure gear pumps must have stronger gears, tighter tolerances, and reinforced housings.

3. Temperature Range

If you’re dealing with high-temperature fluids, choose a gear pump designed for thermal resistance to avoid failure due to material breakdown.

4. Flow Rate Requirements

Determine how much fluid you need to move per unit of time. Gear pumps are highly customizable for flow rate, but oversizing or undersizing can lead to performance issues.

5. Fluid Compatibility

Corrosive or abrasive fluids may require specific gear materials or coatings to extend pump life and maintain performance.

6. Maintenance Needs

Some gear pumps offer easy access for cleaning and maintenance, ideal for industries where downtime is costly.

Common Industrial Applications

Gear pumps are widely used in sectors where accuracy, high pressure, and handling viscous fluids are essential. Here are a few common examples:

Power Plants:

Circulating lube oil in turbines with lube oil pumps.

Petrochemical Industry:

Handling viscous hydrocarbons or resins.

Food Processing:

Transferring syrups, oils, or chocolate.

Manufacturing Plants:

Applying adhesives, paints, and coatings.

Heat Transfer Systems:

Using high temp oil pumps to manage thermal fluids.

Each application has unique requirements, making it essential to match the gear pump’s capabilities to the specific demands of the process.

Maintenance Tips to Maximize Gear Pump Life

Regular maintenance can significantly extend the life of your gear pump. Here are a few tips:

Monitor Seals and Bearings:

These components are subject to wear, especially under high pressure or temperature.

Check for Fluid Contamination:

Clean fluids reduce internal wear and increase longevity.

Lubricate When Necessary:

Some pumps require additional lubrication, particularly when handling abrasive or dry fluids.

Watch for Unusual Noise or Vibration:

These are often early signs of internal wear or misalignment.

Keeping your pump well-maintained ensures uninterrupted operation and reduces the risk of costly breakdowns.

When dealing with viscous liquids, high pressure, or elevated temperatures, not just any pump will do. Gear pumps — especially those built as lube oil pumps or high temp oil pumps — offer the precision, durability, and efficiency required for modern industrial demands.

By understanding your application’s specific requirements and carefully selecting the right gear pump, you’ll not only ensure smooth operations but also extend equipment life and improve overall production performance. In a world where every drop and every second count, choosing the right pump can be a game-changer.