Image Source: unsplash.com

In signage manufacturing, innovation plays a crucial role in creating visually stunning and durable signs that capture attention and leave a lasting impression. Two technologies that have revolutionised the signage industry are wood engraving and water jet cutting.

Wood Engraving: Combining Tradition with Precision

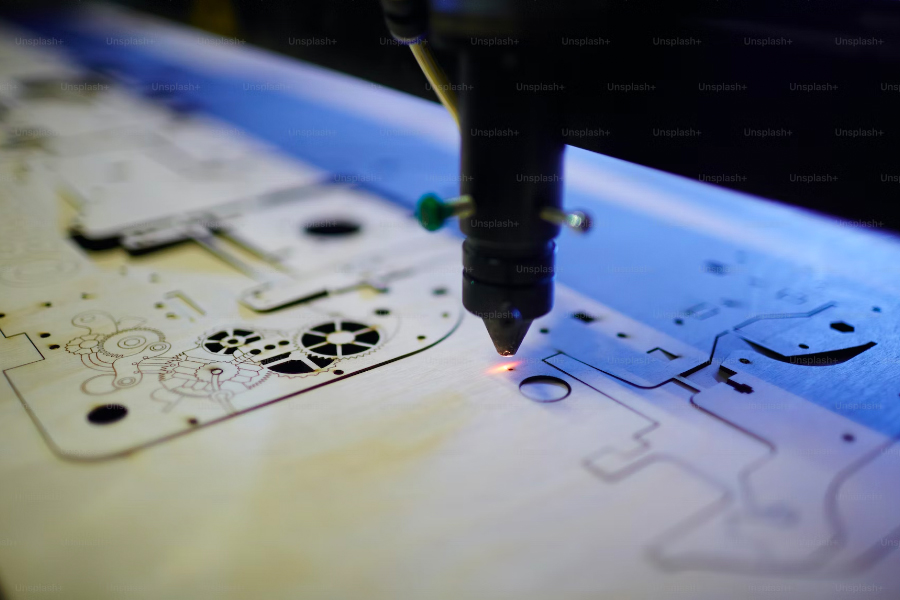

Wood engraving is a technique that combines traditional craftsmanship with modern precision. It uses laser technology to precisely carve intricate designs and patterns onto wooden surfaces. The laser beam removes layers of wood, creating depth and texture, resulting in visually captivating signage.

One of the significant advantages of wood engraving is its ability to bring out the natural beauty and grain of the wood. This technique enables creation of custom signage with a warm and organic aesthetic. Wood engraving is particularly popular for businesses that aim to convey a sense of craftsmanship, heritage, or a connection with nature.

Wood engraving Perth offers exceptional precision and detail, ensuring that even the most intricate designs are accurately reproduced on the wooden surface. This level of precision enables the creation of custom typography, logos, and other graphic elements that enhance brand identity and visibility.

Water Jet Cutting: Precision and Versatility

Water jet cutting is a manufacturing process that utilises a high-pressure jet of water mixed with abrasive particles to precisely cut through various materials, including wood, metal, glass, and stone. In the context of signage manufacturing, water jet cutting provides exceptional precision and versatility.

With water jet cutting Perth, signage manufacturers can achieve intricate shapes and designs with clean edges and smooth finishes. The technology allows for precise lettering, logos, and graphics, enabling businesses to create highly customised and visually appealing signage.

Another advantage of water jet cutting is its versatility in material selection. Whether you choose wood, metal, or composite materials, water jet cutting can accommodate your choice. This flexibility allows businesses to explore different materials and finishes to achieve the desired aesthetic for their signage.

The Benefits of Wood Engraving and Water Jet Cutting for Signage Manufacturing

Visually Striking Results:

Wood engraving and water jet cutting techniques produce signage with exceptional visual appeal. The intricate designs, textures, and finishes created through these processes make a bold statement and attract attention.

Precision:

Both wood engraving and water jet cutting offers unparalleled precision and detail, ensuring that intricate designs and typography are accurately reproduced on signage materials.

Customisation:

Wood engraving and water jet cutting allow businesses to create highly customised signage that reflects their unique brand identity. The ability to incorporate custom logos, typography, and designs enhances brand visibility and recognition.

Durability:

Signage manufactured through wood engraving and water jet cutting techniques is built to last. These processes create business signages that are resistant to wear, weathering, and fading, ensuring long-term durability and visual impact.

Versatility and Material Selection:

Wood engraving and water jet cutting techniques can be applied to a wide range of materials, allowing businesses to choose the perfect material that aligns with their design vision and brand aesthetic.

Take Away

Wood engraving and water jet cutting have revolutionised the world of signage manufacturing. These techniques offer precision, versatility, and exceptional visual appeal, allowing businesses to create custom signage that stands out in the competitive business landscape.

Embrace the innovation and elevate your signage with wood engraving and water jet cutting.

Learn more about wood engraving, water jet cutting, and other signage manufacturing methods as you check out Artcom Fabrication—a Western Australian company offering 3D printing, signage manufacturing, etching, fabrication, engraving, and cutting services.