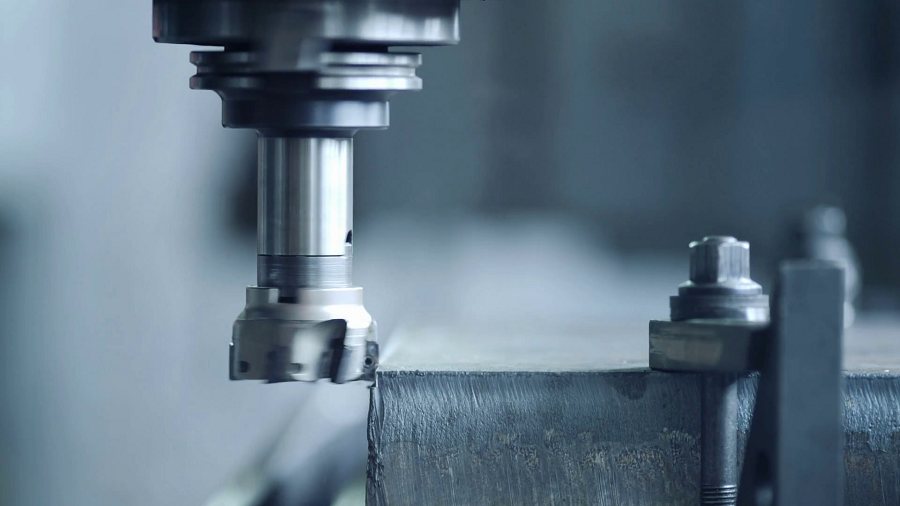

CNC manufacturing, also known as computer numeric control, is a process that involves computer control of machine tools. These tools can be routers, grinders, lathes, and crane lifts. If you have a working CNC machine but aren’t sure how to begin, there are a few things you should know. In order to be successful with CNC manufacturing you need the right tools, and Laszeray Technology, LLC can help you acquire these tools.

Get Some Decent Cutters:

A package of assorted sizes of imported cutters just won’t cut it. You want some decent cutters from a reliable source. Having quality cutters will eliminate a bunch of problems up front. If you are just starting out, you can go with HSS for a better price. You may want carbide as you start to learn more, but for starting out, HSS is more forgiving and less expensive. You will need a few sizes and you should start with ½”, ¼” and 3/16”. If you get anything smaller, it will be hard to learn.

Pay Attention to Chip Buildup:

If your machine doesn’t have flood coolant, get a misting setup and pay attention to chip buildup. Recutting chips isn’t good for the cutters and can lead to breakage. If you are paying attention, then you are watching and you can fiddle with the misters’ nozzle. This way, you can learn how to position it right every time, in order to blow away the chips.

Learn How to Use MDI:

In order to learn how to run your CNC, you will need to learn some basic g-codes so that when you run a real program you have an idea of what you are doing. Start with the cutter higher up and don’t make any moves in the Z-axis to avoid crashing the cutter into anything. Practice with moves in the X and Y until you aren’t making mistakes.

Use a Feeds and Speeds Calculator:

Once you are close to making the first cut, you need feeds and speeds calculate. Figuring out feeds and speeds as a beginner can be frustrating, so the calculate is worth the money.

Avoid Stainless:

Before you make any cuts, there is a lot to get to that point. However, there are some materials you want to avoid for your first cuts. Stick with non-metals, like wood or plastic, or go with brass and aluminum. When you are doing okay with software matters, then start to use mild steel before you move to tougher materials.

Graduate to CAD/CAM:

Once you know how to do the basics, there is still a lot more learning to do. The next step is to become proficient in CAD/CAM. Research the best software for beginners and start mastering.

Experts at Laszeray Technology, LLC have the tools beginners and experts need, in order to succeed at CNC machining.